Embracing Technology: A Must for Today’s Procurement Leaders

In today’s unpredictable business landscape, where raw material costs fluctuate and geopolitical dynamics (like the China +1 strategy) reshape global supply chains, procurement has become more critical than ever for businesses.

Procurement sits at the heart of vast amounts of data scattered across the supply chain—from raw material purchases to final goods delivery. Picture this data in various forms:

- Costing sheets for head and tail spends

- Indexation details

- Logistics costs

- Supplier performance metrics

The challenge? Connecting, analyzing, and presenting this data in a way that enables sound, efficient sourcing strategies. It’s no longer just about collecting data; it’s about leveraging technology to analyze and act on it strategically.

Let’s explore how data and technology can transform procurement across key areas within an organization:-

1. Spends and Part Cost Assessment

Understanding the true cost of components has long been a challenge for procurement teams, largely due to unstructured costing methods. AI-driven costing engines are changing the game by delivering precise cost estimates based on materials, processes, labor, and other variables.

How It Works:

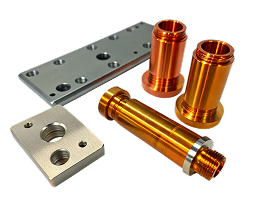

- Upload Design: Procurement managers upload the 3D design of parts or components into the portal.

- Provide Inputs: Specify raw materials (e.g., steel, aluminum alloy), processes (machining, forging, casting), quantities, delivery timelines, etc.

- AI-Driven Costing: The costing engine analyzes the design and inputs to provide an estimated cost, empowering procurement teams to negotiate more effectively with suppliers.

2. Real-Time Supplier Management

Procurement often involves unstructured discussions with suppliers—spanning requirement gathering, cost estimation, purchase order sharing, and new product development updates. Technology enables real-time supplier management through digital dashboards and AI tools that provide comprehensive visibility into supplier performance metrics like quality, cost, delivery adherence, and risks.

Benefits of Digital Dashboards:

- Save Time and Reduce Errors: Automating repetitive tasks like invoicing and order tracking eliminates manual errors and speeds up the procurement cycle.

- Effective Production Planning: Visibility into supplier performance ensures production schedules align with material availability.

- Optimized Inventory: Data-driven insights help manage inventory based on consumption trends, reducing overstocking and waste.

3. Predictive Analytics for Parts and Components

AI-powered predictive analytics helps procurement teams forecast demand for raw materials—often the largest cost driver—while identifying potential disruptions in the supply chain.

Benefits Delivered:

- Defines supplier strategies, inventory levels, and commodity purchases.

- Aids in structuring contracts (e.g., spot buys vs. fixed, length, and supplier diversity).

- Prepares organizations to mitigate risks from political or market disruptions.

Challenges in Adopting Technology in Procurement

While procurement leaders recognize the transformative potential of data and technology, several hurdles often prevent its full adoption:

- Unstructured and Asymmetric Data: Despite plans to transform procurement within the next 5 years, many organizations lack clean, centralized data. Fragmented files across systems and regions create barriers to analysis.

- Low Investment Prioritization: Procurement is traditionally seen as a cost function, resulting in limited budget allocation for its digital transformation compared to demand-side initiatives like CRM and marketing.

- Resistance to Change: Even when tools are deployed, procurement teams may use them half-heartedly due to ingrained habits and lack of training. Resistance to changing workflows can stall adoption.

How to Prioritize Technology in Procurement

To overcome these challenges, companies can form cross-functional teams comprising members from Procurement, IT, Business, and Finance to identify use cases and set priorities for their organization.

Key Use Cases Include:

- Improving visibility into supplier performance.

- Automating routine tasks like quotation requests and purchase orders.

- Enhancing cost transparency for better vendor negotiations.

These foundational steps help select the right technologies to position procurement as a strategic lever for profitable growth.

How OneProc Leads the Way

At OneProc, we leverage cutting-edge technology to transform direct procurement for our clients. By providing real-time visibility into supplier performance and enabling data-driven decision-making, we empower procurement teams to optimize quality, cost, and delivery.

We also work to free your procurement team from routine tasks, allowing them to focus on sourcing core materials that drive your product’s value and differentiation.

Conclusion:

Embracing technology is no longer optional—it’s essential for procurement teams looking to stay competitive in today’s dynamic environment. By addressing data challenges, automating key processes, and leveraging predictive analytics, organizations can transform their procurement functions into a strategic advantage.

Ready to elevate your procurement strategy? Connect with OneProc to learn how we can help.