Make in India: Empowering procurement and strengthening the backbone of Supply chain

Imagine a world where your supply chain is faster, more resilient, and helps you hit those elusive cost optimization targets.

Does it sound too good to be true?

It’s not, and the key to unlocking this potential might just be right at your doorstep—literally.

With the “Make in India” initiative gaining momentum, procurement teams across industries are starting to see the light. Localizing your supply chain doesn’t just offer patriotic appeal—it’s a strategic move that can redefine how you do business. Lower costs, quicker lead times, and a more transparent supplier network are just the beginning.

But here’s the catch: while the opportunities are incredible, navigating the shift can be tricky. How do you maintain quality, avoid bottlenecks, and ensure scalability when switching from global suppliers to local ones?

At OneProc, we are cracking this code. Let’s explore how embracing “Make in India” can help procurement teams not only meet but exceed their targets. Whether you’re a seasoned procurement pro or just starting to explore localization, there’s something here for everyone.

Why “Make in India” Matters to You

As a procurement head, your primary goal is to ensure a smooth supply of direct materials and components. In a world where global supply chains are more fragile than ever—due to geopolitical tensions, shipping delays, or raw material shortages—the “Make in India” initiative offers a practical solution: localizing your supply chain.

Here’s why this matters:

- Reduced Lead Times: Sourcing from local suppliers significantly cuts down the waiting time for parts and raw materials. No more worrying about stuck shipments stuck or higher charges or customs clearances.

- Better Supplier Relationships: Dealing with Indian suppliers means better access to their operations, allowing for real-time communication and collaboration to resolve quality or production issues.

- Support for PLI (Production Linked Incentive) Schemes: Government incentives under PLI schemes reward businesses that manufacture locally. By aligning with “Make in India,” you’re taking advantage of these benefits, which could directly impact your bottom line.

Overcoming Challenges in Localization with OneProc

We know that transitioning from global to local sourcing isn’t always easy. You might be asking, “Will the quality match global standards?” or “Can Indian suppliers scale to meet demand?” That’s where we step in to smoothen this transition.

1. Ensuring Quality Consistency

Many procurement heads worry that local suppliers might not meet the stringent quality standards required. At OneProc, we mitigate this concern through our robust supplier auditing system. We work only with Tier-1 suppliers who meet our rigorous quality checks, including 200+ point assessments. Plus, our AI-enabled technology ensures real-time visibility across the entire supply chain, flagging quality issues before they escalate.

2. Scaling for Demand

Another challenge is ensuring your suppliers can scale production to meet rising demand. OneProc tackles this through multi-supplier strategies, ensuring that you have not just one, but multiple partners who can fulfill your orders. This way, capacity issues are no longer a risk.

3. Cost Control and Efficiency

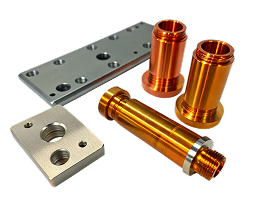

Local doesn’t mean expensive. With OneProc’s zero-based costing (ZBC) approach and extensive market knowledge, we ensure that local sourcing remains cost-effective. Whether it’s steel, aluminum, or injection-molded plastics, we track commodity prices and negotiate competitive rates with Indian suppliers, giving you better cost predictability.

Future-proofing your procurement strategy

Here’s why aligning with this initiative can help you future-proof your procurement processes:

- Geopolitical Independence: With the world’s increasing economic uncertainty, relying on imports from a single region is risky. Diversifying with local suppliers under “Make in India” ensures that your procurement is less vulnerable to external shocks.

- Sustainability and ESG (Environmental, Social, Governance) Alignment: Many global corporations are under pressure to meet sustainability targets. Procuring locally reduces your carbon footprint, aligning your business with ESG goals and building your brand image.

- Increased Agility: When your supply chain is localized, you can respond faster to changes in demand, product modifications, or last-minute engineering changes. No more waiting months for overseas shipments or parts.

Why Choose OneProc?

At OneProc, we understand that “Make in India” is more than just a government directive—it’s a way to unlock new opportunities in procurement. Our deep network of pre-vetted suppliers, cutting-edge AI technology, and on-ground process experts ensure that your localization efforts are seamless, efficient, and cost-effective.

We don’t just source—we partner with you to build a procurement strategy that reduces risk, enhances quality, and optimizes costs.

Are you ready to revolutionize your procurement?

If you’re ready to make your supply chain future-proof, let’s talk. At OneProc, we’re not just helping companies source smarter—we’re transforming the entire procurement ecosystem to be more local, sustainable, and cost-effective.